All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

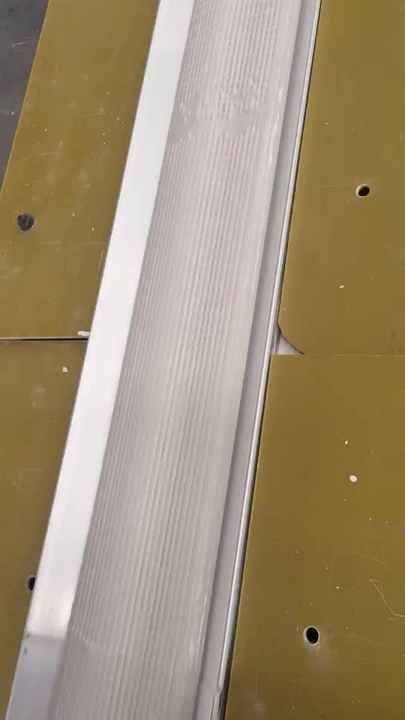

Gypsum cornice production line 5500 pcs one day

No reviews yet

Key attributes

Other attributes

Applicable Industries

Manufacturing Plant, Construction works

Showroom Location

Bangladesh, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan, Japan, Australia, Egypt, Germany, Philippines

Place of Origin

China

Warranty

1 Year

Condition

New

Brand Name

Yuanteng

Raw material

gysum powder,glass fiber,mesh

Working time

300 days

Capacity min.

1000 pcs per day

Capacity max.

30000 pcs per day

Automation

High Degree Automatic or semi

Product name

Gyosum Cornice

After Warranty Service

Spare parts, Field maintenance and repair service

Local Service Location

Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Egypt, United Kingdom, Russia

After-sales Service Provided

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Packaging and delivery

Packaging Details

wooden case,pallet,carton case or others,packing in protected package and put inside of container when ship, delivery by sea or railway depends on customer

Port

Qingdao or others

Supply Ability

Supply Ability

1 Set/Sets per Month

Lead time

| Quantity (sets) | 1 - 1 | > 1 |

| Lead time (days) | 77 | To be negotiated |

Customization

Customized logo

Min. order: 1

Customized packaging

Min. order: 1

Graphic customization

Min. order: 1

For more customization details, message supplier

Know your supplier

Product descriptions from the supplier

>= 1 sets

$25,000.00

Variations

Total options:

Shipping

Shipping solutions for the selected quantity are currently unavailableMembership benefits

Quick refunds on orders under US $1,000Claim now

Purchase detailsProtection with

Purchase details

Protection with

Secure payments

Secure payments![]()

Every payment you make on Alibaba.com is secured with strict SSL encryption and PCI DSS data protection protocols

Refund policy

Refund policy![]()

Claim a refund if your order doesn't ship, is missing, or arrives with product issues